|

SHIELD-CHECK

& ESD DISCHARGE SIMULATOR

Shield-Check

& it's ESD Discharge Simulator, have been designed as a quick

check indicator to quantify the maximum voltage seen inside

a metallized shielding bag. ESD Discharge Simulator (1000D)

delivers, a (HBM) Human body model charge of 1000 volts. Shield-Check

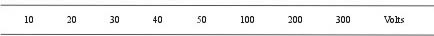

(SC-0-300) records the peak voltage seen inside the bag, via

a row of LED's sensing 10-20-30-40-50-100-200- 300 volts.

The maximum voltage sensed will remain visible until the operator

presses the reset switch.

|

Our

portable mains powdered ESD Discharge simulator and

near credit card size Shield-Check sensor, can be used

for a quick evaluation of new and used shielding bags.

Complete with Stainless steel Discharge probe, Reference

plate, and test leads.

SC-0-300 POWER: 3 x 3 volt lithium coin cell batteries

CR2032

1000D POWER: mains 120/240Ac

SC-0-300 SIZE: 106mm x 60mm x 21mm

1000D SIZE: 150mm x 115mm x 57mm

|

Questions

and Answers about Shield-Check

Why use a (HBM) Human Body Model of 1000 volts?

Other Voltages may be used at the operators discretion, however

users should be sensitive to the voltage breakdown limitations

of the material under test as well as the various components

used in the Shield- Check sensor.

Why

is the sensor unit near credit card size?

This allows the user to measure the performance of almost

any size of metallized shielding bag.

Why

should the user not touch the probe, bag under test or reference

plate, whilst delivering 1000v (HBM) from the discharge simulator?

The sensor detects the differential voltage between top and

bottom sensing discs through the shielding bag. If the users

touches the probe, bag, or reference plate, the 1000v (HBM)

will reference to the user rather than reference plate.

What

if no voltage LED's light after the 1000v discharge has been

made?

This is due to the effective shielding of the bag under test

I.E. less than 10 volts has been sensed.

If

the 10 volt LED lights what voltage has been sensed?

10 volts or greater than 10 volts but less than 20 volts.

The same principal applies for 20 volts 30 volts etc.,

Will

a good quality large shielding bag show a lower voltage reading

than a good quality small shielding bag?

Yes because the metallized layer will absorb the 1000v, over

a larger surface area.

Will

the sensor detect pin holes in the surface of a shielding

bag?

No! because the 1000 volt (HBM) is absorbed by the metal layer

of the shielding bag. A shielding bag is an electrical Faraday

cage, not a water tight container. A clean cut through a shielding

bag when laid flat might not be detected by the sensor. The

users visual inspection should identify cuts and holes.

If

I cut a big hole out of the back of the bag will the sensor

detect it?

Only if the top and bottom sensing discs on Shield-Check are

making direct contact with the bag material under test.

When

I deliver 1000v (HBM) from the discharge simulator, if the

bag is good (less than 10 volts) and shows no voltage reading

on the sensor, even through the power LED is on. How do I

know than I have carried out a test on that shielding bag.

Less obvious is that the 1000v relay inside the simulator

will click, or the bag may move slightly when the change is

applied. But to verify both simulator and sensor, remove the

sensor from the bag place it on the reference plate and put

the discharge probe on the sensors top disc. Then discharge

directly, your reading will be in excess of 300 volts.

What

if two or more voltage LED's light at the same time?

A spilt signal or (Ringing) has occurred through the bag under

test. The sensor receives two or more peak voltage signals

at the same time indicating poor shielding.

What

Charge remains between the probe and reference plate after

the user has taken the previous reading?

When not delivering a pulse, a 10 meg Ohm resistor between

the probe and reference plate ensures no residual charge remains.

What

if I cut the heat sealed edges off one or both sides of the

shielding bag?

The sensor has been designed to check the shielding ability

of the bag in it's formed state. Not the ability of the metallized

film used to produce the bag. By cutting off the sealed edges

you no longer have a bag to measure just the material.

What

makes a metallized shielding bag bad?

The nose edge of the bag excessively creased or damaged, the

sealed edges of the bag inconsistent, the metallized layer

too thin, folds in the bag or snowball effect where the bag

has been creased all over.

Why

is the voltage sensed nearly always the same if the bag end

is open or closed?

The capacitance of the air gap at the open end of the bag

is greater than the resistance of the metallized layer around

the bag. The 1000 volts will always find the quickest path

to Ground/Earth. (In our case the reference plate)

TECHNICAL

DESCRIPTION OF SHIELD-CHECK SYSTEM

Shieldcheck provides a quick and convenient check, on the

effectiveness of a metallized shielding bags capability to

protect its contents against Electro-static Discharge (ESD).

A compact sender provides a 1000volt human body model (HBM)

discharge which is received by a battery operated sensor unit

placed inside the bag. The choice of 1000volt for the test

pluse is to avoid break down of the material under test. A

bounce free leading edge is achieved by use of a mercury wetted

relay.

The sensor unit detects a voltage pulse between its two sensor

plates, and remembers the level which has been exceeded displaying

it by means of the eight LED display. The nominal levels of

detection are as follows.

High speed integrated circuits ensure that fast pulses are

registered. DC coupling permits easy checking of the threshold

levels.

Shieldcheck and its discharge simulator are based on the EIA541

capacitive probe method. When not delivering a pulse, a 10meg

Ohm resistor between the probe and earth reference plate ensures

no residual charge remains from previous use. Amongst other

Shielding is a function of the resistance around the bag so

the pulse amplitude will be dependent on where in the bag

the Shieldcheck sensor is placed. When a pulse is delivered,

one of the LEDs will light unless the sensor detects less

than 10 volts between its plates. This indicates that the

peak exceeds the indication but not the next higher value.

Thus when the 20volt LED lights, the peak was between 20 and

380volts.

SHIELD-CHECK SC-0-300

Switch on Shield-Check via the right angle switch below part

number label.

Make sure the POWER ON LED is visible.

Insert Shield-Check into shielding bag.

When (HBM) Human Body Model pulse has occurred from 1000D

Discharge unit the maximum voltage sensed will remain until

the operator has pressed the reset switch. (Using a pen or

pointed object)

If NO LED has been illuminated this is due to the effective

shielding of the bag i.e. 0-9 volts sensed. If a voltage greater

than 10 volts has been sensed, one of the eight LEDs will

light until reset.

To change batteries unscrew the 4 self tapping screw in the

rear of the case. Remove all three batteries CR2032 type,

and replace. The + positive of the battery should make contact

with the battery clip. The-negative of the battery should

make contact with the PCB. Make sure that when not in use

the unit is switch OFF.

ESD

DISCHARGE SIMULATOR 1000D

Connect appropriate country plug to mains lead. Make sure

that the voltage select switch is in the correct position

i.e. 120v/240v. The unit has a 100ma fuse located in the rear,

to protect against electrical damage. Plug in to mains socket

and switch on.

Switch on neon front panel power switch. (Marked ON/OFF)

Connect black test lead in to GND socket, and red test lead

into 1000 volts socket using 4mm banana plug ends. Attach

stainless steel reference plant to the other end of the black

test lead, and attach the small circular probe 30mm high 25mm

diameter, to the other end of the Red test lead.

When Shield-Check is in position, make sure that the material

under test and Shield-Check are making contact with the reference

plate. Place the circular probe on the surface of the bag

over Shield-Check sensor plate.

Press the Black discharge button to deliver 1000 Volts (HBM).

Make sure that the operator does not touch the bag under test,

the reference plate or stainless steel probe

|

![]()