|

Installation

Installatio

procedure

1 The floor must

be thy, free of any alien materials and level. (reference:

should maintain a level surface over a length of 3m with a

maximum offset of about 3mm)

2 Concrete floor must be smoothed and when copper tapes are

to applied to ceramic tiles and wooder floor, any holes, cracks,

gaps. etc. should be completely clogged with filler.

3 Tile and adhesive should be stored on the site under normal

temperature(25t) for at least 24 hours pnorto beginning installation

and shall be stored under normal temperature(25 t)for at least

48 hours after completion of work.

4 Tile of same LOT should be used for repeated process.

5 It is strongly recommended to use adhesive approved by this

firm, and a thorough mixing is required before use.

. Size of adhesive applying spatula (groove intervals: 1.0mm,

groove width: 2.0mm, groove height: 2.0mm)

. Using appropriate size spatula, apply conductive adhesive

evenly over the floor.

. To ensure good cohesion, be sure to keep open time(15 minutes)

and finish work within workable period of tirne(1 hour).

6 Upon elapse

of drying time for adhesive, tiles are to be pressed while

working toward outside from th middle of tile alignment line.

7 For welding,

V-shape groove in the depth of about 2/3 tile thickness will

be made along tile joints wilE 48 hours have left following

the laying work of tiles and adhesive has hardened.

8 Using PVC welding

rod of 3-4mm diameter, welding is performed with welder.

9 Any protruding

parts in welded area will be cutoff with knife to become flush

with adjacent areas.

10 When additional

24 hours have lapsed following the completion of the above

processes, the finishec surface will be cleaned off with neutral

detergent using a sponge.

11 Upon completion

of laying processes, entire area will be evenly pressed with

a roller weighing 80kg for perfect adhesiveage and seating.

Caution

.Any excessive

adhesive remnant on the finished tile surface must be cleaned

oft with a soft cloth before being dried.

. Care should be

taken not to expose the finished surface to the sun, heat

or temperature above 30C before adhesive is properly hardened(48

hours), for there is a risk of undesirable material expansion.

.Do not walk on

the finished floor until adhesive has completely gone through

a hardening process that normally takes 48 hours.

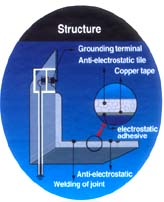

Grounding

KOSTAT Tiles primarily

used for eliminating static electricity and should therefore

be grounded so that any absorbed electricity can be discharged

to outside. The method of grounding can be selected depending

on the site conditions and preference of user.

Use of grounding

terminals on building

Route the copper tape(copper wire) of sufficient length remaning

from laying work toward grounding terminal and connect to

ground card for final installation at the ground terminal.

Where no grounding

terminal is present

Connect to ground mode via steel steel structure on the site.

Maintenance

. Never apply wax on the surface of products.

. Sand or any other alien material should be removed from

the floor since they may cause damage to the surface.

. The product is susceptible to filth from asphalt, lip stick,

some adhesive material, rubber wheels and rubber-backed carpets,

and should be protected from lighted cigarettes.

. Any dirt can be removed by usinq neutral deterqent, but

the deterqent should be removed by wiping the affected area

with lightly wet cloth.

|

![]()